| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader |

| Surface Finishing | Polished |

| Country of Origin | India |

| Feature | Easy To Fit, Non Breakable |

| Click to view more | |

Product Details

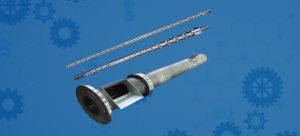

With many polymers, grooved-feed extruders exhibit 20-40% higher output per rpm compared to a smooth feed bore of the same diameter extruder. The grooved feed section enhances solids conveying and amplifies extruder pumping action, resulting in increased output at a given extruder rpm. This not only reduces energy input into the polymer but also lowers the melt temperature.

The grooved feed is employed to achieve high shear and enhance the transportation of material.

Grooved Feed can enhance output and decrease melt temperature. Achieving the proper melting of the material relies on a higher coefficient of friction between granules and the screw and barrel. Therefore, having a grooved feed in the barrel is imperative for the processing of polymer. This, however, requires a higher volume of cold water for cooling.

It requires a special screw design, unlike those used for smooth bore extruders, with a size range of 25 mm to 200 mm. The grooved feed is available in a comprehensive range of designs and models.

It is ideal for use in various applications such as plastic extruder machines, rubber machines, single screw extrusion plants, and more.