| Business Type | Manufacturer, Supplier, Trader |

| Size | 14mm - 300mm Dia |

| Surface Finishing | Polished |

| Country of Origin | India |

| Click to view more | |

Product Details

The feed screw is the heart of the blow molding system. All of your processing preparation is developed in the extruder. If the temperature is not at the proper set point, or if the material is not properly mixed by the time it is discharged, you won’t be able to do much about it in the accumulator head. (That said, a good heating system on the accumulator head is also important to maintain a constant temperature.)

Blow molding is employed in the manufacture of hollow plastic parts, creating common components like PET bottles, HDPE jugs, and jerry cans. Variations on the process include extrusion blow molding (EBM), injection blow molding (IBM), and injection stretch blow molding (ISBM). Thermoforming

In thermoforming, plastic sheet is heated to a pliable temperature then shaped into a part by a male and female mold with the help of a vacuum. Categorized as thin-gauge or thick-gauge, the process is used to create products like clamshells, trays, and cups.

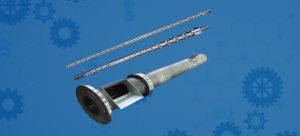

Screw design is the first step in good parison formation, and a major move toward achieving lower overall cycle times. Screw speed should be variable to allow for different resins, parts, and operating needs. Variable speed control will also give fine output adjustment.

We can create new designs based on your formula and capacity, and improve upon your existing design. If troubleshooting is needed or if you want to increase machine power by changing the extrusion screw barrel size, we’ve got you covered. Whether you have detailed drawings or not, you can talk to us about your sourcing requirements. Our screws are carefully engineered with geometry to match the exact needs of your process, ensuring high throughput, supreme mix, and melt quality for optimum component life.